Communications industry applications

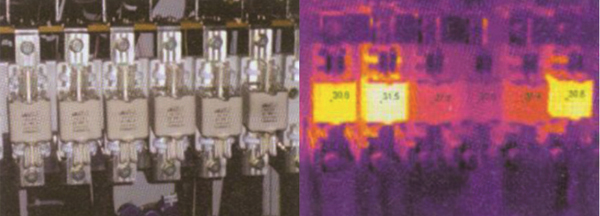

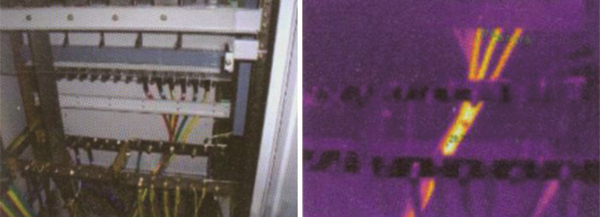

Switching power applications

Switching power supplies are sensitive to temperature. When its temperature exceeds a certain range, it will be interrupted and even damaged. Therefore it needs for temperature measurement regularly to avoid overheating. Switching power supply may generate excessive temperature components, such as AC input switch, rectifier module, load cables, DC fuse and so on. The use of thermal imaging can quickly detect the temperature of the switching power supply components, accurately position point of failure to ensure the normal operation of the system.

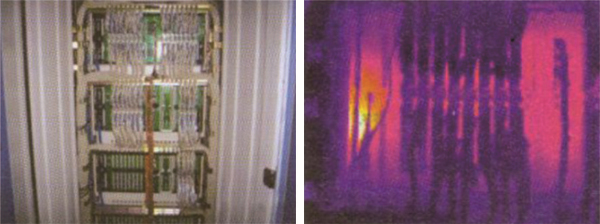

Communications equipment

Such as switches, servers, communication network devices are microelectronic devices, the power per unit volume density of them is relatively large. The operating temperature of electronic components directly affects its stable operation. Operators measure the temperature rise of each board regularly, and compare the measurement results to generally understand operating status of the device, and thus hidden danger can be found in time.

Such as switches, servers, communication network devices are microelectronic devices, the power per unit volume density of them is relatively large. The operating temperature of electronic components directly affects its stable operation. Operators measure the temperature rise of each board regularly, and compare the measurement results to generally understand operating status of the device, and thus hidden danger can be found in time.

UPS-- uninterruptible power supply detection

UPS is highly integrated electronic equipment. It will generate a lot of heat while working. Under normal circumstances, UPS cooling system can have a good control to the temperature. But the internal temperature rise of the UPS will be caused by the rise of the load, the circuit board dust increases, the air filter clogging and other problems. If not timely solve troubles, it will cause serious consequences. Both because of its high integration, there are features such as high-pressure. Through the thermal imager, we can be able to know the distribution of the internal temperature of the UPS, and to determine whether out-of-range.

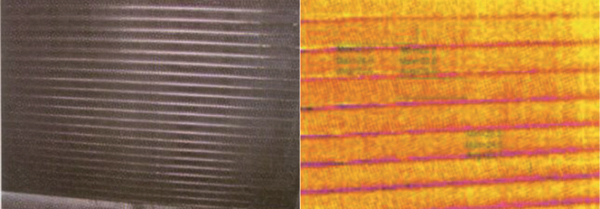

The detection of air conditioning in computer room

Comparing with air-conditioned rooms, computer rooms and program-controlled switchboard rooms are not only different on the temperature, humidity, air cleaner, but also on the device itself. Through conduct the temperature testing of the evaporator, condenser, transmission brass and compressor while air condition in computer working. You can easily find the working status of the air conditioning to ensure the most economical energy efficiency, and thus to improve the cooling efficiency, and make the engine room equipment safe.

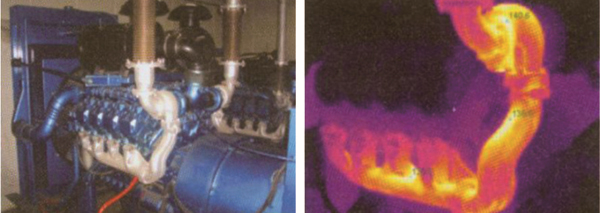

The detection of oil engine generator set

In communications companies, oil engine generator set as a AC power after power cut quickly provide a stable, qualified AC power. Oil engine generator set has a complete set of cooling and lubricating system, but we still need to observe whether the oil machine maintain the normal temperature range while it working, to ensure the normal operation of oil engine generator set.

In communications companies, oil engine generator set as a AC power after power cut quickly provide a stable, qualified AC power. Oil engine generator set has a complete set of cooling and lubricating system, but we still need to observe whether the oil machine maintain the normal temperature range while it working, to ensure the normal operation of oil engine generator set.

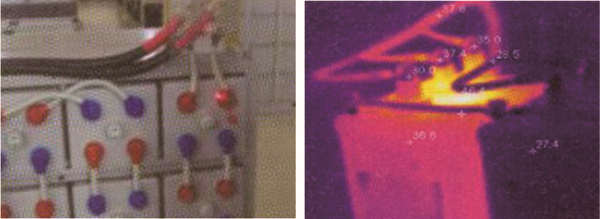

Battery detection

Battery is an important part of the DC power supply system in the communication power supply system. While Battery discharging, if the battery internal short circuit, battery connector strip poor contact, screws not tightened, in the case of large current discharge, the fault location will appear elevated temperatures. Usually only be observed through hand contact and thermometer. There is a certain risk, but may be omissions. Using Infrared imager, operators can conduct temperature testing on each of the connecting terminals of the respective monomers in the entire assembled battery during battery discharging. This test area is wider, there is no blind spot.