DLSC-D Series

Products list

- Uncooled Infrared FPA Detector

- DLC160(25μm)

- DLB384(35μm)

- DLC384(25μm)

- DLD384(17μm)

- DLC640(25μm)

- DLD640(17μm)

- Thermal Imaging Module

- D740G — Uncooled FPA Module

- D780G — Uncooled FPA Module

- B-Series — Uncooled FPA Module

- D900-Series — Cooled FPA Module

- D840/D880 series Module

- Industry Temperature Measurement Thermal imaging camera

- LT3/LT7 series 160*120/384*288

- T31 series 160*120

- T4/T8 series 160*120/384*288

- DL700 — Portable HD infrared camera

- Online temperature measurement thermal imaging camera

- DM60 — Online monitoring

- dm63 Online Front-end Temperature

- dm66 Online Front-end Temperature

- Dedicated Type Thermal Imaging Camera

- F2 — Fire Fighting

- TE-W2 — Handheld body temperature rapid screening

- DM60-W — Online body temperature screening

- GF706 — Handheld infrared gas detection thermal imaging camera

- Handheld infrared security observation

- S240 Uncooled Monocular

- S230 — Thermal Imaging Monocular

- S730 — Portable thermal imaging binocular

- S750M — Thermal Imaging Binocular

- S930H — Thermal Imaging Binocular

- Online observation thermal imaging camera

- DLD-L Series

- DLD-D Series

- DLD-S Series

- DLD-J Series

- DLD-B100

- DLD-B150

- DLD-M240

- DLD-M600

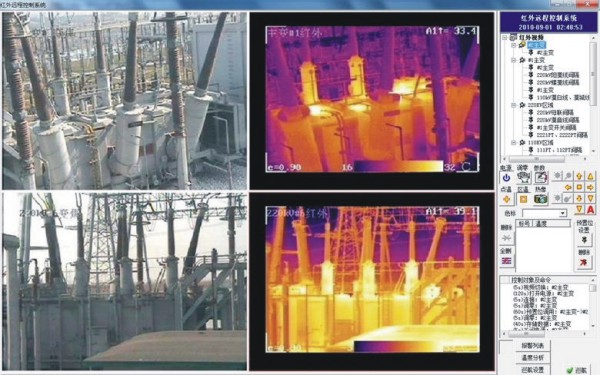

DLSC-D Series

Features

◆ Front end temperature measurement

◆ Real time video output, no delay

◆ can monitor @ zero illumination, smoke , rain and fog

◆ Fast and accurate measurement ,Excellent homogeneity

◆ Thermal imaging compress and network transmission.

◆ International advanced level intelligent target identification system

◆ Auto Cruise

◆ Management of various security events and devices.

◆ Can work smoothly in atrocious weather condition

◆ Easy report creation

◆ Can monitor with Mobile phone, real time

◆ IEC61850 protocol compatible

◆ Easy installation

.jpg)

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

|

Item |

DLSC-D40 |

DLSC-D75 |

|

|

Detector characteristics |

Detector Type |

Uncooled FPA microbolometer |

|

|

resolution |

384×288 |

||

|

Thermal Image |

FOV/Min Foucs |

16°×12°/0.5m |

8°×6°/3m |

|

IFOV |

0.88mrad |

0.44mrad |

|

|

Thermal sensitivity |

≤0.06℃@30℃ |

||

|

Frame Frequancy |

50/60Hz |

||

|

Focus |

Auto/Manual |

||

|

Spectral range |

8~14μm |

||

|

CCD |

Zoom |

6X optical Zoom |

|

|

pixel |

1.3m(dpi) |

||

|

Horizontal resolution |

600(TVL) |

||

|

Sensor |

795*596 |

||

|

Min Illumination |

0.005(Lux) |

||

|

PTZ |

Horizontal Rotating Angle |

0°~360°continuous rotation |

|

|

Presets |

Max 255 |

||

|

Mounting Way & pitching angle |

Top Mounting -90°~+90° |

||

|

measruement |

Measurement range |

-20 ℃~+500 ℃ |

|

|

measurement correction |

Auto/Manual |

||

|

Measurement accuracy |

±2℃ or ±2% of reading, whichever is greeater |

||

|

Temperature mode |

Free Setting in the software |

||

|

Image Storage |

Raw image capture |

Raw images realtime transfer cia client control software,the images are analyzable and measureable |

|

|

Image Storage |

H.264 real-time recording |

||

|

Single image capture in BMP format |

|||

|

Power supply |

External Power in |

220AC |

|

|

Power Consumption |

≤75W( @ 25℃normal operation ) |

||

|

Environment |

Operating temperature |

-40℃~ +60℃ |

|

|

Encapsulation |

IP66 |

||

|

Humidity |

|||

|

Automatic Device recognition |

Automatic recognize the effective target device based on the thermal imaging taken by the system to make sure the validity of the inspection. |

||

|

False alarm prevention System |

All the temperature are getting from the effective target and can be set to only take the temperature of the marked devices ,the interference hotspot will be automatic eliminated thus to avoid the false alarms. |

||

|

management of the detailed device working status |

Build up manage system of all the devices and parts ,all the temperatures of the devices in the cover of the thermal imaging camera will be record and analysed. The system can locate the exact position of the alarm area. |

||

|

Auto cruise |

system using PTZ with preset function and 128 presets can be set in the system. Several auto cruise plan are available, so can realize totally automatic operation. inspect the devices several times a day ,automatic early warning, automatic output report forms etc. it can obviously reduce the human on sight inspections and improve the working efficiency . |

||

|

Automatic early warning |

The system will output alarm with words and voice when abnormal temperatures are detected in cruise ,it will give indication to the operator in order to track the fault position and get rid of the fault. |

||

|

Automatic report creation |

The system software can generate single thermal imaging analysis report of the device joint or comprehensive report which show the every recording temperature and the temperature change trend of the specified target. |

||

|

Panorama picture |

the system can generate wide view, high-precision ,360 degree panorama picture of the target scheme. |

||

|

Front end measurement |

All the temperatures are taken by the front end thermal camera but not from the computer and the camera output video stream with temperature data. |

||

|

Dual field of View. Assist recognition |

The system contain a thermal imaging camera and a visual camera. So the visual camera can assist to identify the target positions to find out the overheat point in time. |

||

|

Low Bandwidth |

Low bandwidth working mode. The bandwidth will not more than 0.8MBps when temperature data and video stream transmit synchronously. |

||

|

SDK |

realtime control SDK |

||

|

imaging processing SDK |

|||

|

intelligent thermal imaging transformer device recognition SDK |

|||

|

Remote control Client SDK |

|||

|

WEB control client SDK |

|||

|

Development support |

Immediately response, 24hours on sight support. |

||

|

Protocol support |

IEC60870-5-104 |

||

| * Content | |

| Product Name | |

| Your Name | |

| Company | |

| Tel./Fax. | |

| Msn/Skype | |