Solar industryapplications

Quality testing ofsolar modules

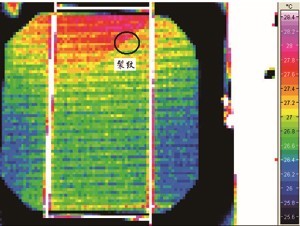

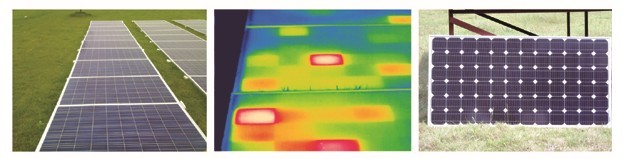

When solar modules in the case of short-circuit, the resistance of monolithic solar cells is too large, leading to local "hot spot" effect. Using infrared camera to detect can effectively improve product quality, and cost savings.

Automatic detection technology R & D of solar modules welding

Using the infrared temperature measurement technology, we can detect all the welding area of the solar cell module prior to lamination and dynamically monitor the welding quality of battery and interconnection when solar cell modules are in large-scale production. Thus we can timely find problems in the welding process, and this help to ensure the welding quality. It greatly reduces the cost of production, and the annual savings is nearly 50 million. At the same time, it also increases production efficiency, from the original manual testing ninety pieces to three hundred and fifty daily.

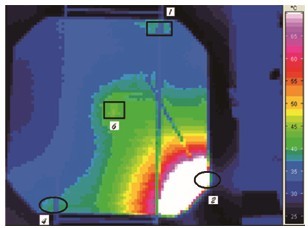

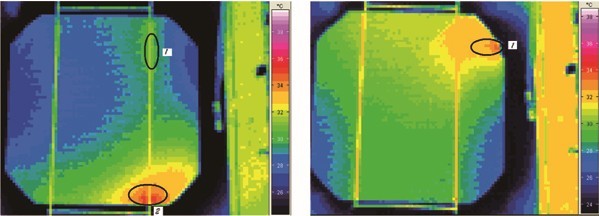

The leakage current detection of single crystal silicon solar cells

The leakage current occurred mainly in three areas: the edge, thin gate line and the main electrode.

(1) In terms of process, the leakage at the edge is likely to be caused by the edge-nodes which may not be removed clean.

(2) The leakage current of the thin gate line and surrounding of the main electrode generally occurs under positive bias, therefore it is likely to cause by the diffusion layer failures, and of course, it also may be caused by sintering overheated.

(3) The leakage current of the main electrode center generally occurs under reverse bias. It may be caused by which diffusion layer cross-contaminate aluminum particles when battery stacked.

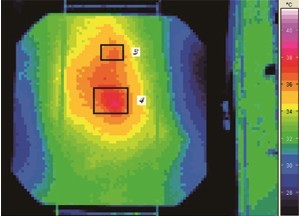

The detection ofsolar cellscracked